Mercury Woody Wagon project- Part 1

1949 Mercury "Woody" wagon project

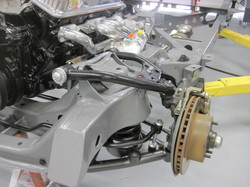

I bought this old woody project last year as a retirement project, and 'cause I just love the old woody wagons. This one needs a LOT of work, but it's also already had some very cool work done to it. Most importantly to me, is that it already has the wood kit purchased (the wood kits for Merc's are crazy expensive 'cause they're so rare), and 'cause the prior owner already did the majority of the work to "Pancake" the roof. Pancaking is when you remove metal from above the top of the window line of the body. 1949 through 1951 Ford and Mercury wagons were some of the most iconic woodies ever (especially 'cause they were some of the few two-door wagons), but they had a disproportionally tall roofline that never looked right to me. This car has had a subtle amount of material removed that gives it a much better look. It also had a 1969 Camaro front clip welded in which opens up a lot of opportunities for improved braking and handling, as well as more modern engine reliability and performance.

On the interior, I want modern amenities (power windows, three-point seat belts, excellent sound system) and in Northern California it MUST have effective A/C. Aftermarket systems (Vintage Air, etc) do a good job cooling air. But they don't move ENOUGH air for an interior this size. So, I plan on running two evaporator units.