Corvette Build-Phase 2

THE PETS

Chevelles

1965 Corvette

Motorcycles and Track Days

The Corvette Build- Drivetrain and Interior

The Corvette Build- Wiring and Final Assembly (Phase 1)

The Corvette Buildup (Phase 2) chassis conversion

More Corvette Phase 2 progress

Corvette Phase 3 Final Assembly and Glamour pictures

1949 Mercury Woody Wagon project- Part 1

Chico house

Mercury Woody Project- Part 2

Mercury Woody Project- Part 3

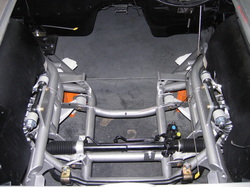

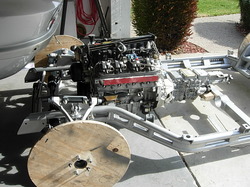

Phase 2 begins.

I put a deposit down for an SR III tube frame chassis back around May, with a planned delivery date around the end of October, 2014. In late September I started taking the car apart with the ulimate goal of lifting the body to do a bunch of work, and have it ready for the new frame.